Fuelles protectores para maquinaria

Los fuelles se adaptan al movimiento del mecanismo al que acompañan, expandiéndose o contrayéndose.

Los fuelles protectores están diseñados para proteger a las personas, las máquinas y los sistemas articulados que se encuentran junto a ellos. Los fuelles se adaptan al movimiento del mecanismo al que acompañan, expandiéndose o contrayéndose.

Ventajas de nuestros fuelles protectores

- Personalización: ofrecemos fuelles de la marca HEMA con diferentes diseños adaptados a su aplicación, ya sea con materiales especiales para aplicaciones láser, plasma o soldadura, versiones especiales para tecnología médica o diseños para aplicaciones de alta velocidad.

- Alta calidad del producto: los fuelles han sido expuestos a exhaustivas pruebas de producto y materiales para garantizar su calidad.

- Protección integral: disponemos de una amplia gama de productos de fuelles, desde fuelles individuales hasta sistemas completos listos para instalar como pared trasera de la máquina, con sus guías y accesorios.

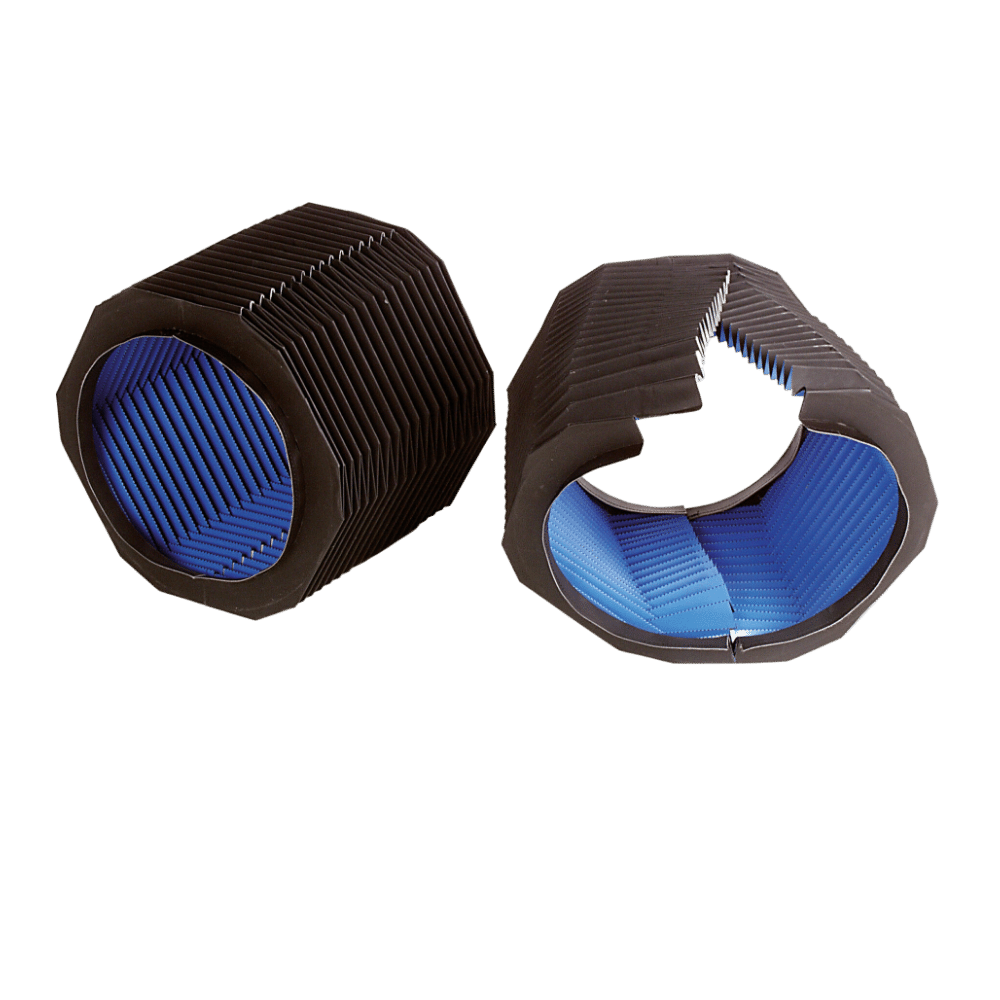

Fuelles elásticos

Los fuelles elásticos -o con forma de acordeón- se utilizan, por ejemplo, para aplicaciones en mesas elevadoras o guías de maquinaria en general. También disponemos de fuelles redondos cosidos, como alternativa a los muelles metálicos en espiral para proteger ejes, barras y husillos.

El fuelle Laminat es muy resistente y estable debido a la combinación de sus materiales. Como fuelle para máquinas de corte (láser, plasma o chorro de agua), el fuelle Elastic protege los componentes mecánicos como husillos y guías, además de proteger el haz del láser.

La serie Elastic se puede combinar de diferentes maneras. Los componentes básicos, así como el material, la forma, el tipo de procesamiento y las dimensiones, se ajustan individualmente según sus necesidades.

Fuelles Samurai

La característica especial de la serie de fuelles “Samurai” son las laminas metálicas que se unen al borde superior de los pliegues. Refuerzan el fuelle y lo protegen de las virutas calientes o afiladas, es decir, actúa como protector del protector. Gracias a esta protección, la serie Samurai es muy adecuada para aplicaciones HSC.

Fuelle W

Las máquinas modernas son cada vez más compactas, dejando poco espacio para las cubiertas protectoras. Con el fuelle W cumplimos dos requisitos importantes: por un lado, estos fuelles requieren un menor espacio de instalación que los modelos convencionales y, por otro lado, logran cubrir cursos más largos.

Los fuelles W requieren menos pliegues para lograr la misma longitud de extensión. Este ahorro de material reduce el espacio requerido para el fuelle comprimido.

Otra ventaja del fuelle W es su peso: al no necesitar bastidores de apoyo, es más ligero que los sistemas estándar y permite una mejor dinámica en el movimiento de los ejes.

Fuelles para aplicaciones especiales

Para aplicaciones con requisitos especiales también ofrecemos fuelles fabricados con PVC blando, discos de goma o telas revestidas. Los fuelles de PVC blando son resistentes al aceite, álcalis y ácidos, además de al agua y al polvo.

Nuestros fuelles de discos de goma son de la más alta calidad. Asimismo, visualmente son las cubiertas protectoras más atractivas para pistones y husillos. También están diseñados a prueba de fugas.

Recomendamos el uso de fuelles de tela de caucho si los fuelles están especialmente sujetos a un desgaste intenso, condiciones de alta presión o altas temperaturas de hasta 200 °C.

Techos

Si el espacio de procesamiento de las maquinas no se cierra durante el proceso de fabricación, las virutas y los refrigerantes de la máquina pueden colarse en el entorno de producción y contaminarlo.

Nuestras cubiertas de techo están diseñadas de forma personalizada para cada máquina, ya sea para la configuración inicial de la máquina o para su modernización.

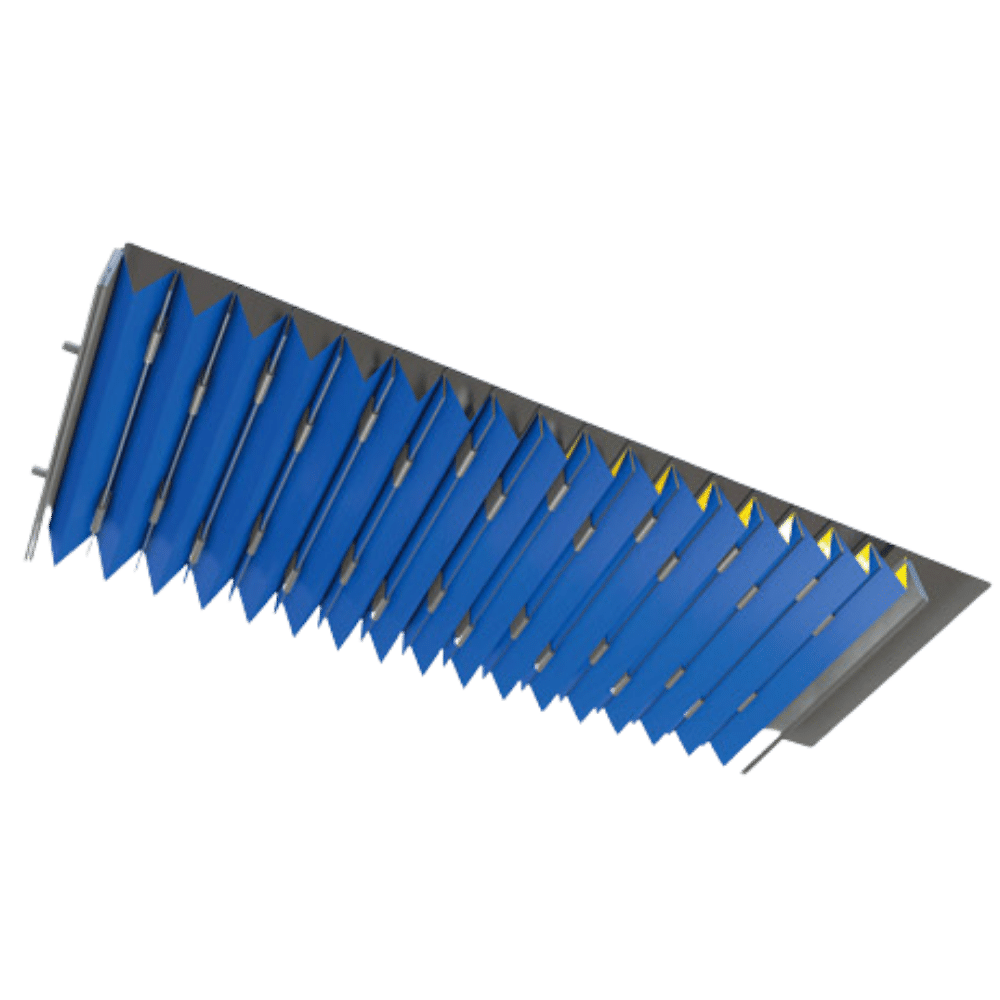

Sistema de cubierta de techo X-Velo

La cubierta del techo X-Velo retiene tanto virutas como refrigerantes en la máquina, evitando la contaminación del entorno de fabricación.

Este sistema X-Velo es adecuado tanto para la adaptación inicial de la maquina como para su actualización.

- Longitud personalizada de hasta 12 m. Se pueden solicitar soluciones personalizadas

- Altas velocidades de hasta 75 m/minuto

- Material transparente y ligero

- Sin torceduras gracias a nuestros sistemas de sujeción especiales

- Fácil de limpiar (perfil abierto)

- La cubierta es fácil de atornillar. La rosca de tornillo atraviesa todo el perfil

- Los rieles de guía se incluyen con la entrega

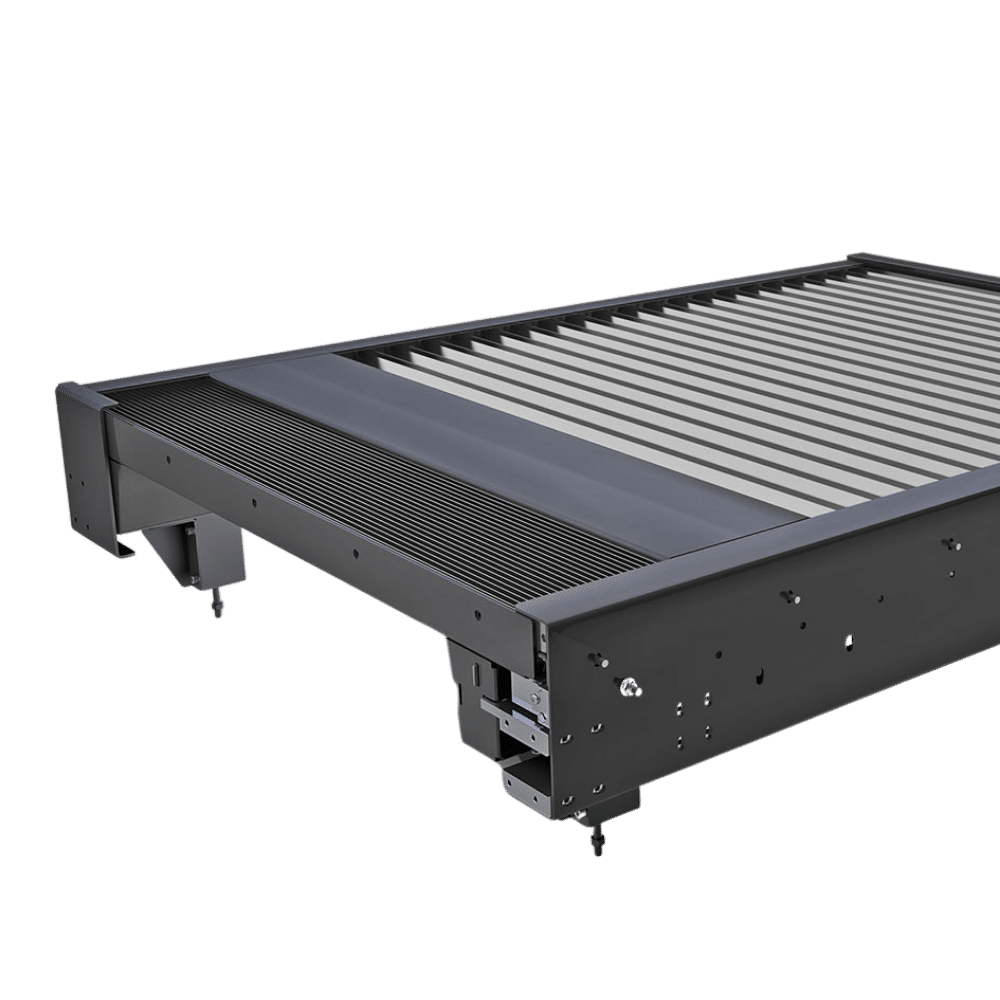

Sistema de pared trasera

Los sistemas de pared trasera protegen las partes sensibles de la máquina de virutas y refrigerantes durante el proceso de producción. El sistema de pared trasera se fabrica con fuelles y se entrega listo para su instalación en la máquina. Los tiempos de instalación se reducen significativamente, puesto que el fabricante de la máquina ya no necesita el montaje de los fuelles individuales, debido a que monta un sistema completo.

Para proteger los ejes, se utilizan fuelles con láminas de acero inoxidable, los denominados fuelles «Samurai«.

Todos los sistemas de pared trasera y sus componentes están diseñados de manera personalizada para cada máquina, y pueden alcanzar velocidades de desplazamiento de hasta 120 m/min.